Wire Form Design Considerations Why Wire Forming Wire forming can produce custom complex designs in a variety of metals Our technicians can set up our wire forming equipment to develop very complex designs with any shape and with complete accuracy Spiros Custom Wire Forms Benefits of Wire Forming Why use custom wire forming

Looking for a custom solution We do more than stock products Contact us to see how our customization capabilities can help Wire forming involves applying force to a length of wire to alter its shape Raw stock feeds into wire forming machinery either from wire coils weighing anywhere from 5 to 5 000 pounds or as blank forms in a hopper Wire forming or bending is the process of taking wire from spooled coils or a blank length and bending it into specific forms using state of the art equipment and techniques Wire shapes are used across diverse industries such as formed components and material handling solutions among other applications What are the types of wire forms

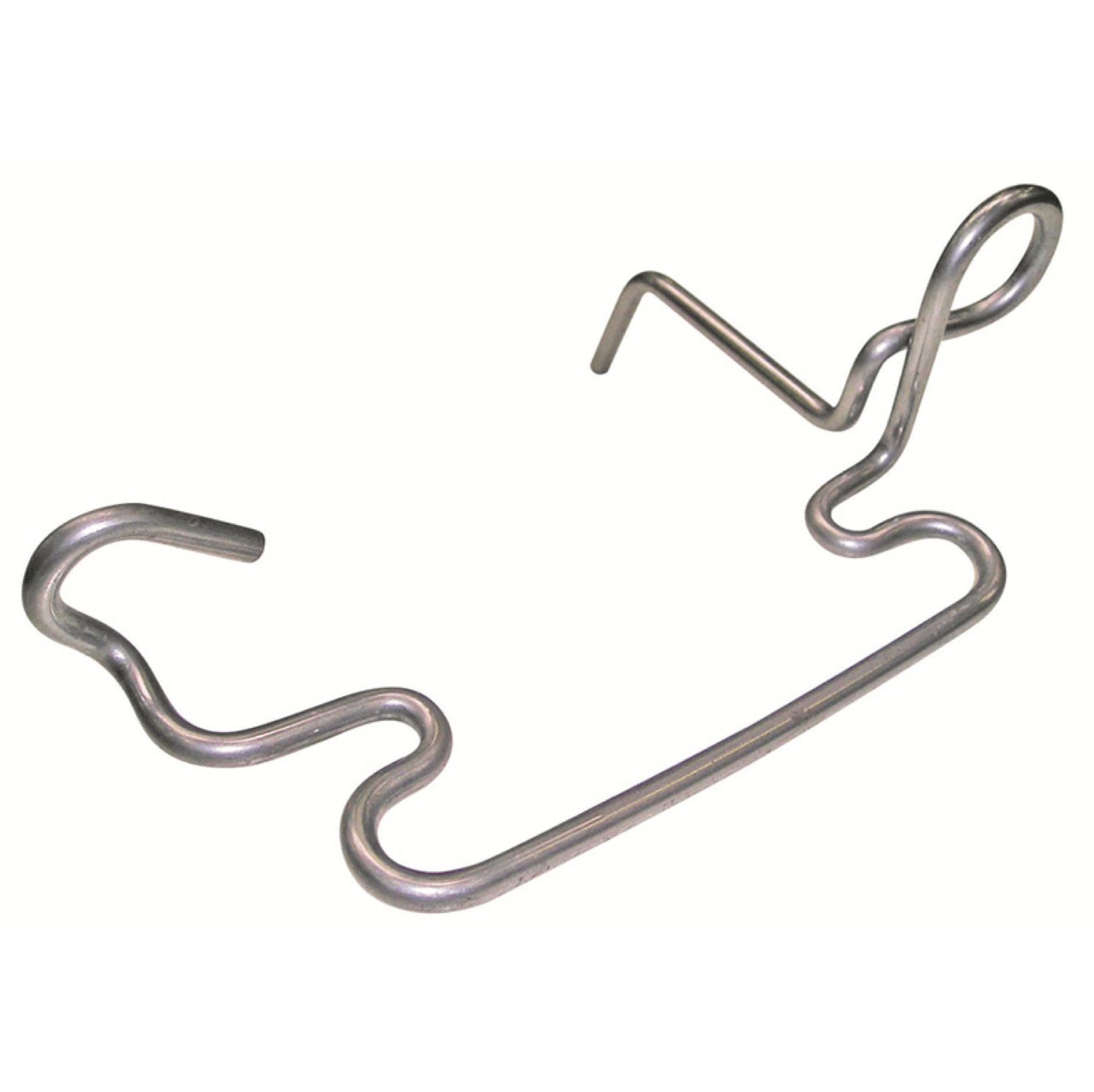

Wire Form

Wire Form

https://plymouthspring.com/wp-content/uploads/2021/06/wire-forms-1-1-2048x1365.jpg

Custom Wire Forms Wireform Prototyping Spiros Industries

https://spirosind.com/wp-content/uploads/2011/11/Wire-Forms-Assortment.jpg

Wire Forms Linal Inc Global Supplier Of Custom Manufactured

https://linal.com/wp-content/uploads/2014/04/Wire-Form-4.jpg

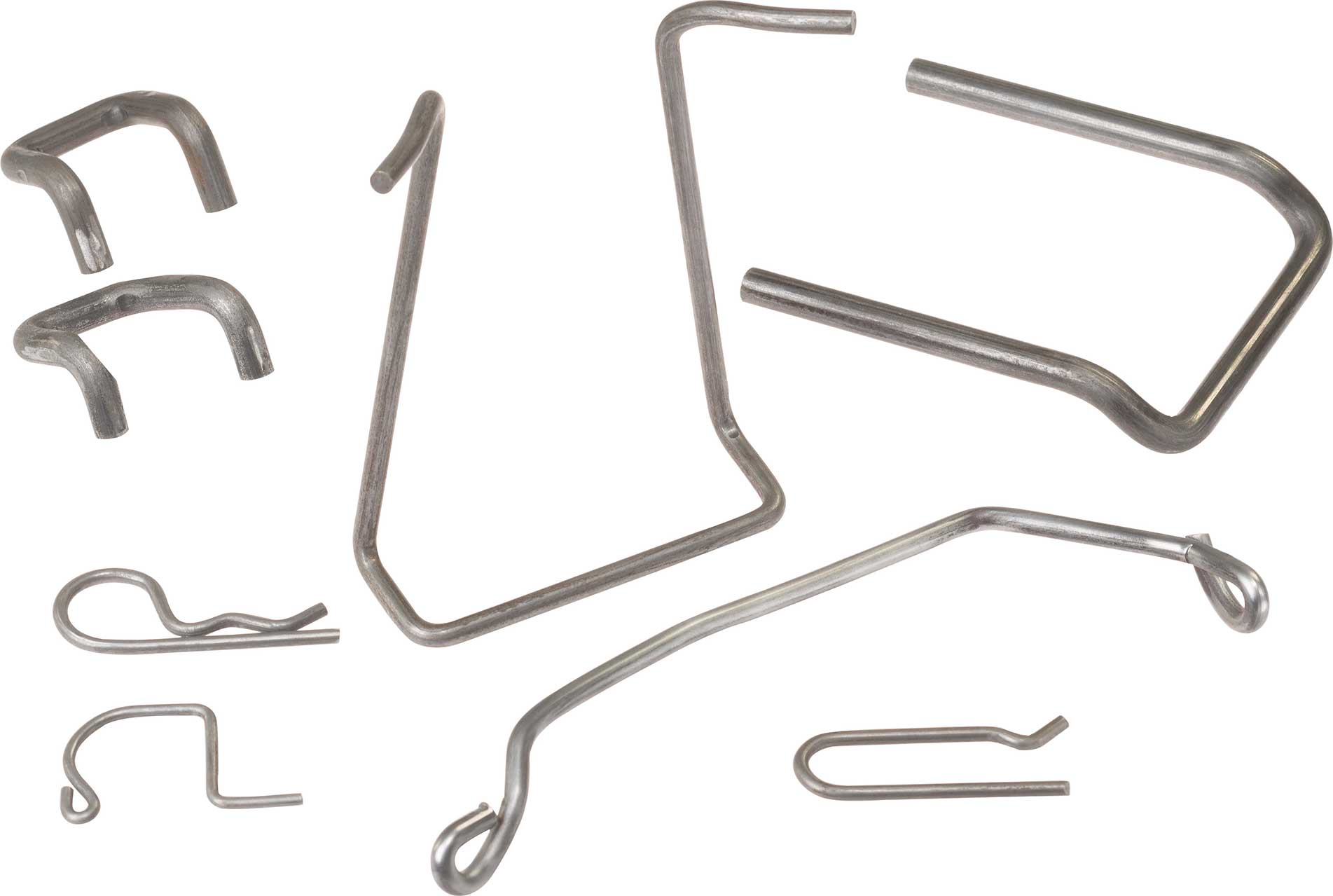

Wire Forms Capabilities Equipment List Secondary Equipment Quality Certification Acceptable File Formats Wire Products Company offers Wire Form Assemblies for all your varying needs and demands Our Wire Form Assemblies have flexible designs that provide future scope for any improvisation MW Components produces custom wire forms in a wide variety of wire sizes from 006 through 1 00 and in lengths up to 36 We produce a number of wire formed products including several styles of pins like cotter pins hitch pins and lock pins as well as S hooks D rings figure 8 hooks grip clips hog rings and others

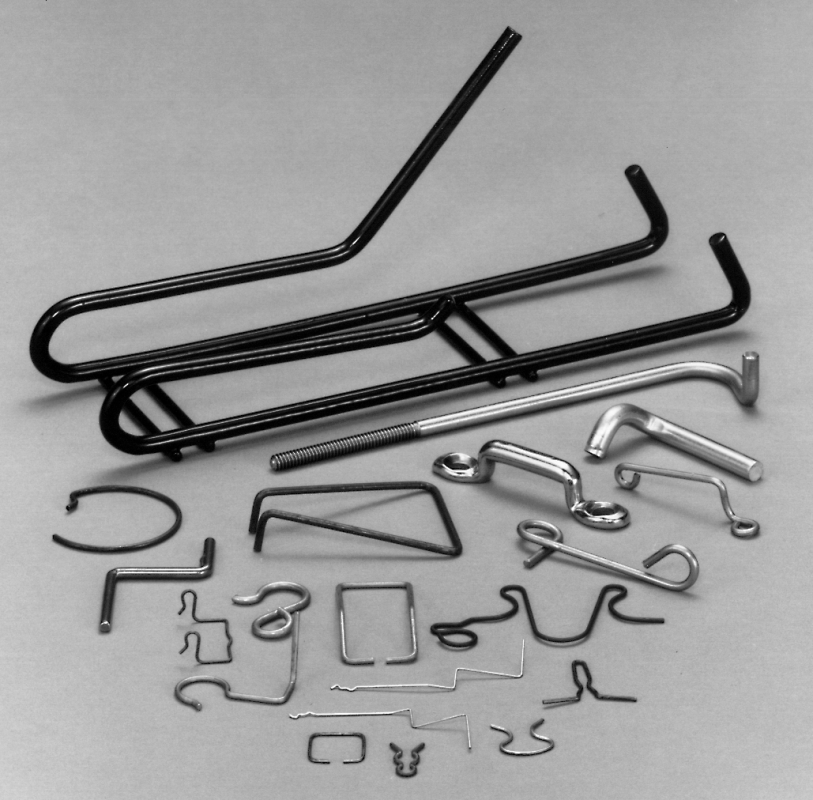

Wire forming is a general term for a series of processes that apply force to wire materials in an attempt to change their contour Specific wire forming techniques may include piercing bending shearing chamfering swaging and others depending on size shape and configuration requirements Contact a knowledgeable Madsen Steel Wire Products professional at 260 829 6561 or contact us right here on the website Uses for Wire Handle Products A variety of industries incorporate wire handle products plus wire shelf brackets into their facilities and stores They re useful for several applications including Buckets Pots Utensils Shelves

More picture related to Wire Form

Wire Forming Services CNC Wire Forms Salco Engineering

https://www.salcoeng.com/wp-content/uploads/2015/06/Screen-Shot-2015-06-10-at-9.01.18-AM.png

Spring Wire Forms Metal And Wire Products Company

https://metalandwire.com/images/WiresPage.jpg

Accurate Wire And Strip Forming Inc Wire Forms

https://www.accuratewsf.com/images/wire_forms_two_large.png

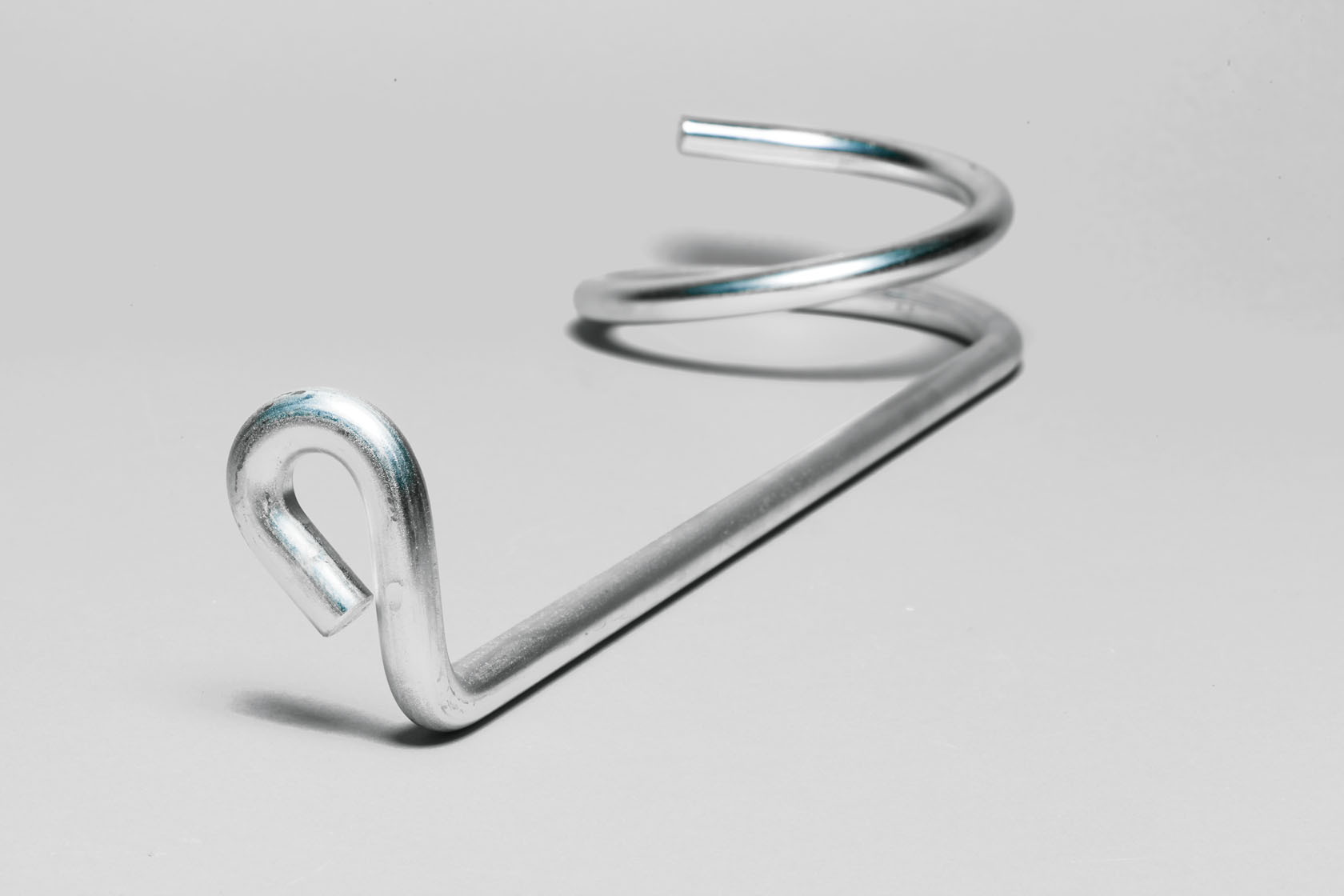

Wire forms or more specifically wire forming is a fabrication technique that utilizes blanks of metal wire which is manipulated into standard or customized shapes for a variety of applications Performance Through Technology Precision Wire Forms is an industry leading manufacturer of Wire Forms Tube Forms and Assemblies Since its conception in 1997 Precision Wire Forms has quickly and firmly established itself as a leader and innovator in the wire and tube forming industry We are able to meet our customers needs

Wire form manufacturing typically happens in four distinct steps First because of the versatility of wire forms the specifications must be laid down before the project can begin Typically wire forms are designed for the individual application to a specific set of specifications That being said we typically create wire forms from wire Wire Diameter Range and Wire Material Type Specializing in building long term partnerships with OEMs Master Spring Wire Form Co has the expertise and latest equipment to manufacture the difficult or impossible to make wire forms We have a wide range of CNC wire forming machines that can manufacture custom wire forms with diameters

Wire Forms Wyser International Corp

http://www.wyser.tw/comm/upimage/p_170719_03199.jpg

Wire Forming

http://www.wisconsinstamping.com/wp-content/uploads/2015/03/IMG_8263.jpg

Wire Form - MW Components produces custom wire forms in a wide variety of wire sizes from 006 through 1 00 and in lengths up to 36 We produce a number of wire formed products including several styles of pins like cotter pins hitch pins and lock pins as well as S hooks D rings figure 8 hooks grip clips hog rings and others