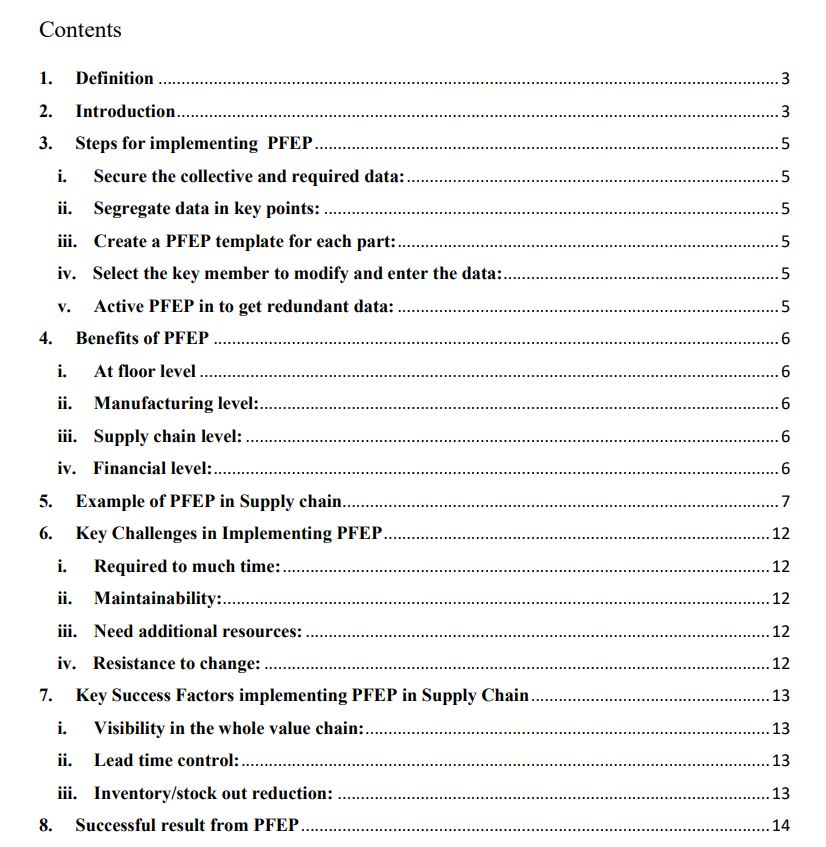

Plan For Every Part Template Learn the Plan For Every Part PFEP meaning along with lean manufacturing principles to balance your supply chain s inventory levels

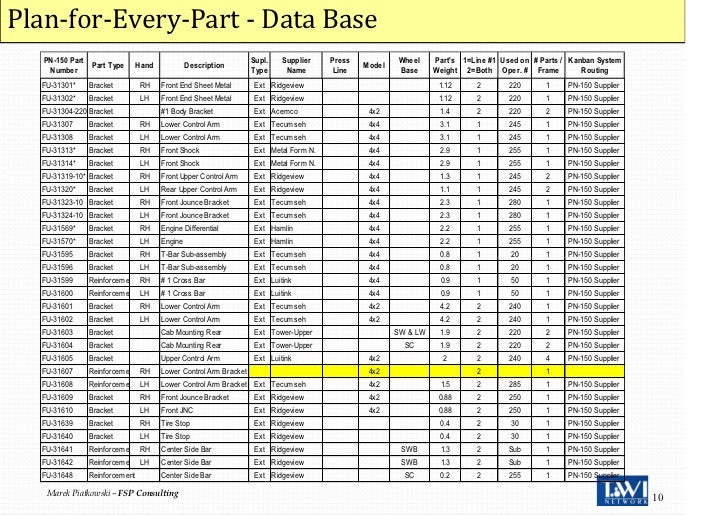

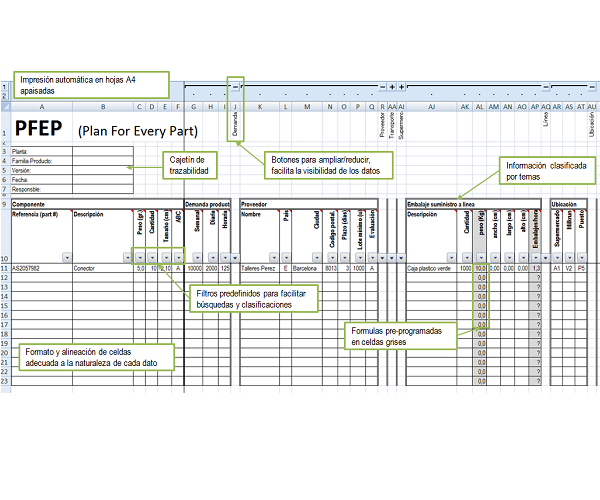

The first step in creating a lean material handling system is to develop a Plan for Every Part PFEP Essentially an electronic spreadsheet or database the PFEP fosters precise accurate and controlled inventory reduction while serving as the foundation for the continuous improvement of a plant s material handling system Plan For Every Part PFEP is an essential Lean tool for mapping optimizing and managing input data to maintain a high performing supply chain

Plan For Every Part Template

Plan For Every Part Template

https://image.slidesharecdn.com/pfep-introduction-120821053859-phpapp01/95/pfep-introduction-10-728.jpg?cb=1345527572

Plan For Every Part Template

https://leanbox.es/wp-content/uploads/PFEP-1-1.png

PFEP Plan For Every Part Creative Safety Supply

https://cdn11.bigcommerce.com/s-10c6f/product_images/uploaded_images/pfep.jpg

What is Plan for Every Part PFEP PFEP an acronym is originating from the Lean Community The PFEP is used to define a plan at part level for the most efficient replenishment and movement of each and every part used in business through the complete Supply Value Chain Get Excess and Obsolete Inventory Policy Plan For Every Part PFEP A collaborative application used to document the storage and delivery plan for every part with the ability to support execution and analysis Part Data Accuracy in a Single Location PFEP defines where and how parts are received stored and delivered in the plant as well as how the material is moved

Plan For Every Part PFEP is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste and increasing productivity PFEP database contains all data related to products with details about sourcing procurement storage manufacturing and sales and distribution This helps businesses gain 1 Determine how to house PFEP data 2 Determine required data elements for your business 3 Segment your parts by PFEP impact and repeat About loopPFEP Nothing improves operations like having a plan

More picture related to Plan For Every Part Template

Plan For Every Part Template

https://flevy.com/images/slideshows/2173/3.gif

Plan For Every Part Template Guide

https://www.scmdojo.com/wp-content/uploads/2021/10/PFEP-Content-2.jpg

Plan For Every Part Template

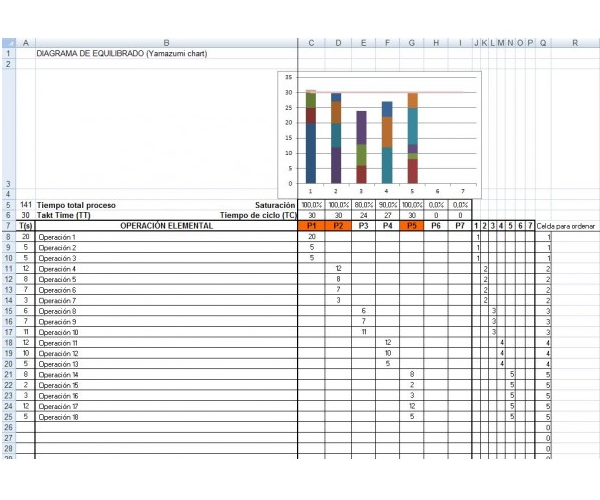

https://leanbox.es/wp-content/uploads/Equilibrado-1.png

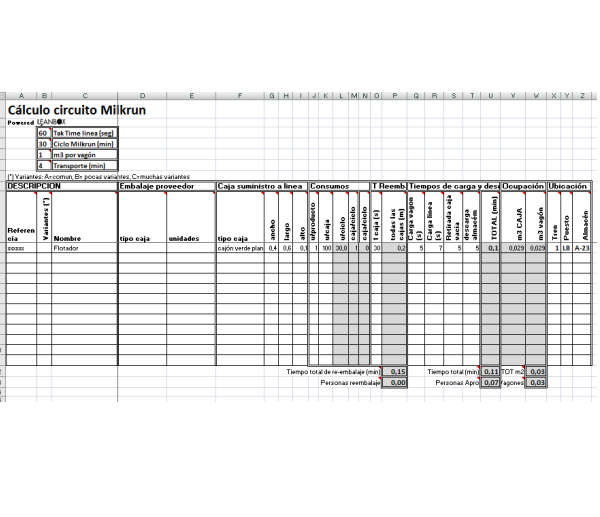

A PFEP is vital to the successful planning of tugger train replenishment routes They allow managers to sort material needs by manufacturing cell or line station creating a step by step inventory list that can be serviced by a single looping route Part data listed on the PFEP weights sizes number of units also help to choose the Warehouse PFEP Plan For Every Part an acronym is originating from the Lean Community The PFEP is used to define a plan at part level for the most efficient replenishment and movement of each and every part used in business through the complete Supply Value Chain

Plan For Every Part PFEP is an essential Lean tool for mapping optimizing and managing input data to maintain a high performing supply chain The specific supply chain pain points or goals that drive leaders to deploy PFEP vary from broad applications like deploying a new Lean Company Management System to narrow ones such as reducing inventory at a specific plant Plan For Every Part A detailed plan for each part used in a production process showing everything relevant to managing the process with no errors or waste This is a critical tool in the Toyota Production System

PFEP Plan For Every Part Optimize Your Entire Supply Chain

https://www.leandna.com/wp-content/uploads/2017/10/Pasted-image-at-2017_10_24-04_22-PM.png

Plan For Every Part Template

https://leanbox.es/wp-content/uploads/PlanillaMilkrun-600x517.png

Plan For Every Part Template - Plan For Every Part PFEP is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste and increasing productivity PFEP database contains all data related to products with details about sourcing procurement storage manufacturing and sales and distribution This helps businesses gain