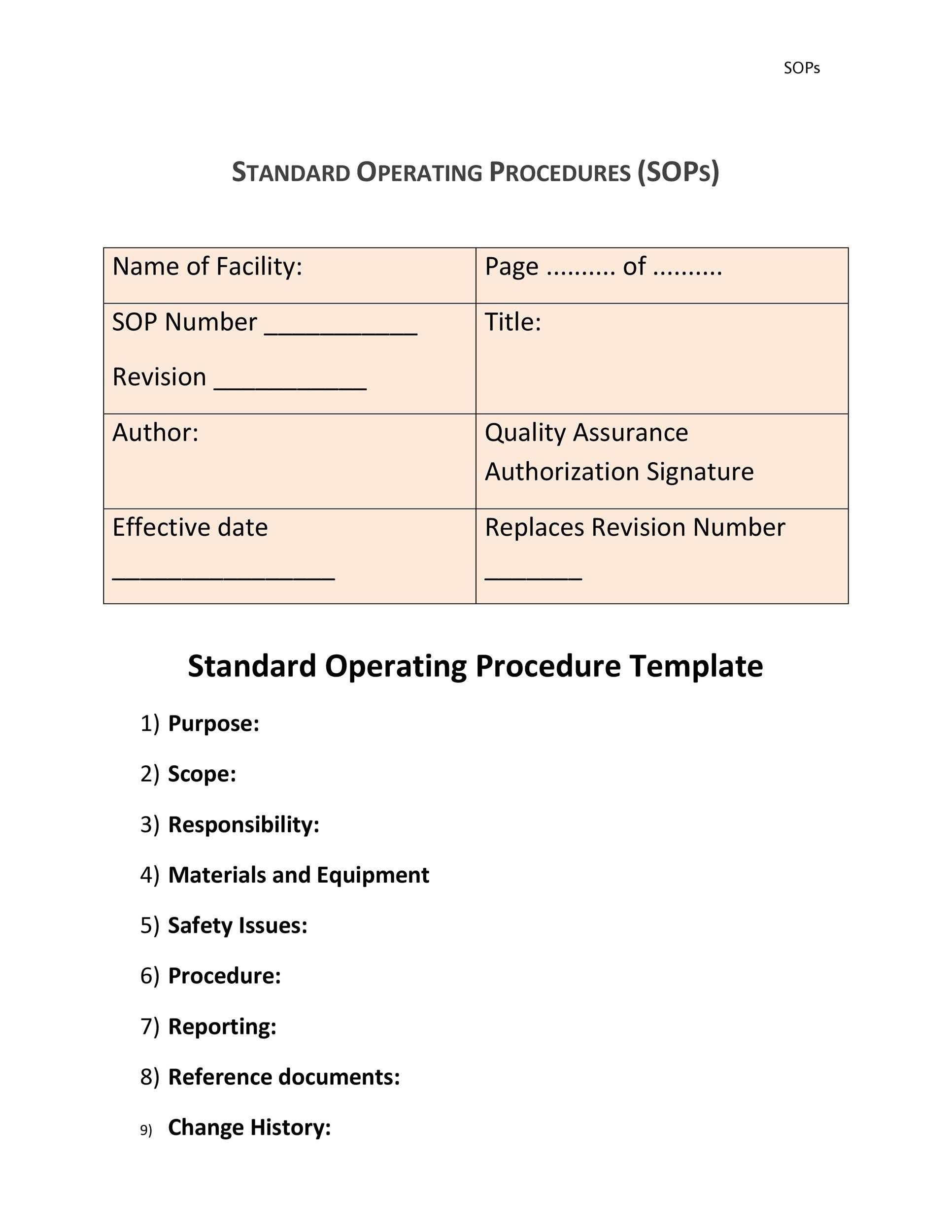

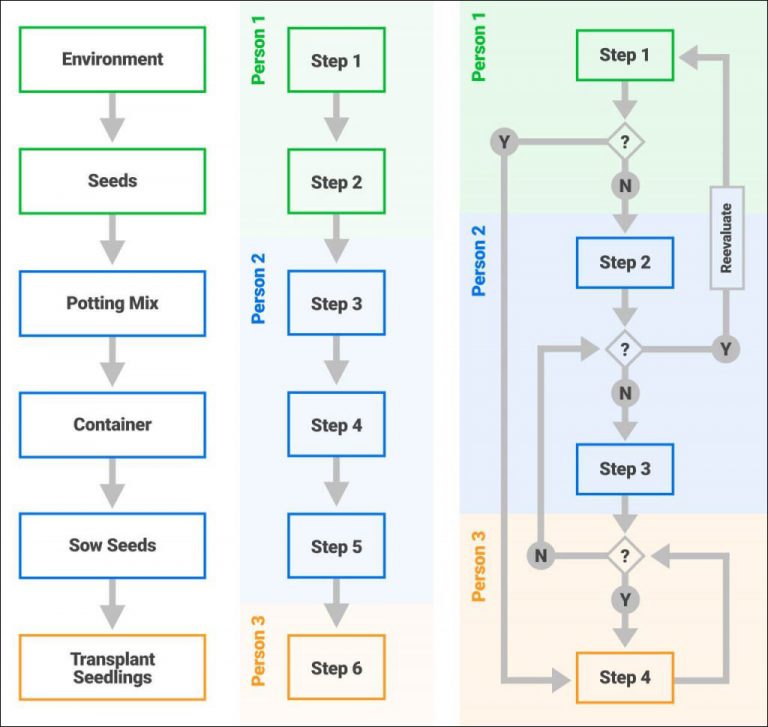

Manufacturing Standard Operating Procedure What are manufacturing SOPs Manufacturing SOPs are step by step work instructions that guide operators through a task SOP is an abbreviation for standard operating procedure The main goal of setting up an SOP is to structure and standardize the way in which work is done

A standard operating procedure or SOP is a step by step set of instructions to guide team members to perform tasks in a consistent manner SOPs are particularly important for complex tasks that must conform to regulatory standards SOPs are also critical to ensuring efficient effort with little variation and high quality in output 1 Standardization The very purpose of a standard operating procedure is to establish a standard and consistent way of completing a task Assigning approved SOPs ensures workers always perform tasks in the same manner across manufacturing facilities and production lines

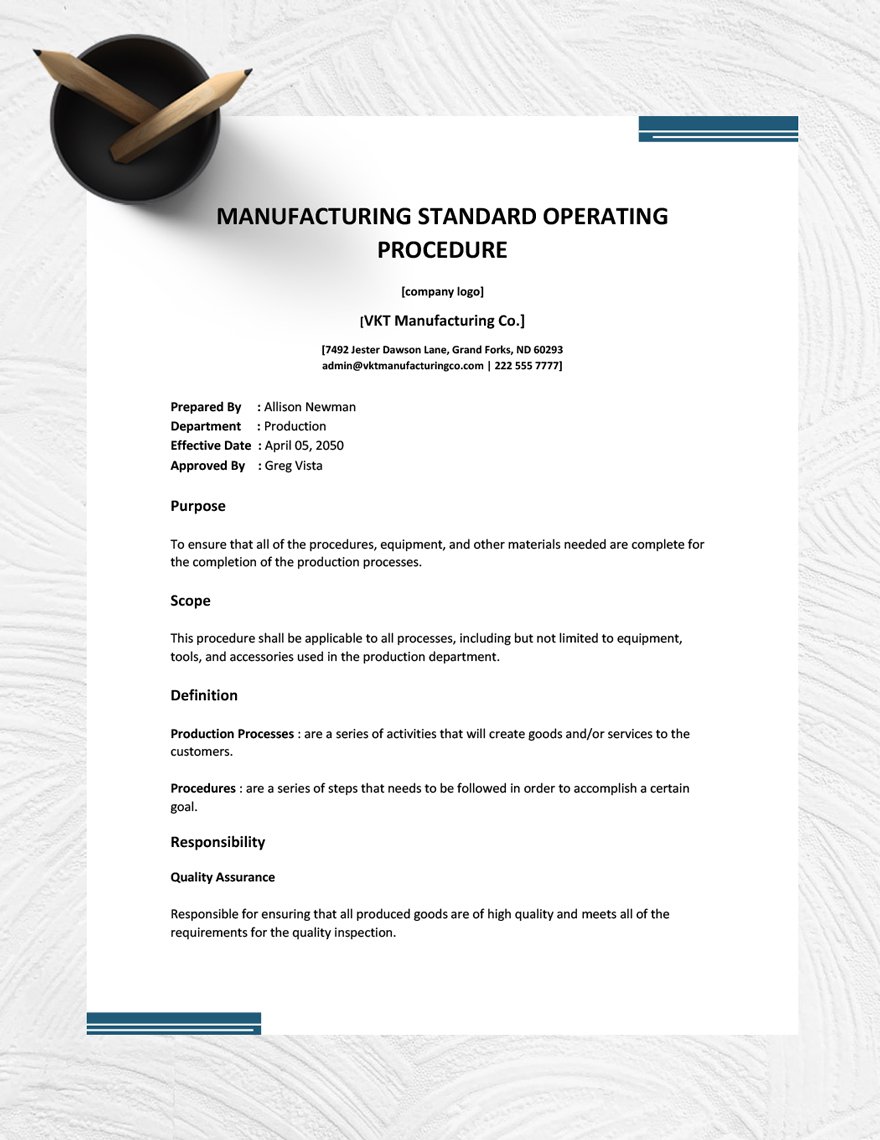

Manufacturing Standard Operating Procedure

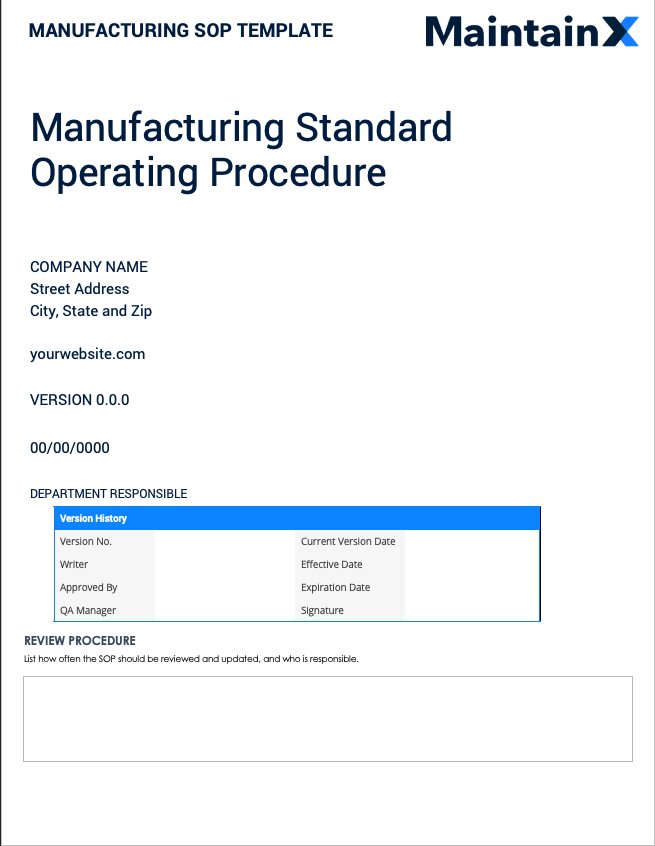

Manufacturing Standard Operating Procedure

http://templatelab.com/wp-content/uploads/2015/11/SOP-Templates-29.jpg?w=790

Manufacturing Procedure Template

https://images.template.net/88931/manufacturing-standard-operating-procedure-template-20beg.jpg

Free Standard Operating Templates

https://software.getmaintainx.com/hs-fs/hubfs/manufacturingsop.png?width=1200&height=1551&name=manufacturingsop.png

A Manufacturing Standard Operating Procedure is a step by step instruction guide for carrying out specific tasks in a manufacturing process It is a foundational document that details the procedures to accomplish a particular job safely and effectively ensuring product quality and worker safety Manufacturing SOPs are step by step instructions that document protocols and best practices for performing specific manufacturing tasks and organizational processes SOPs act as a reference tool for employees providing a basis for process standardization that ensures quality and safety

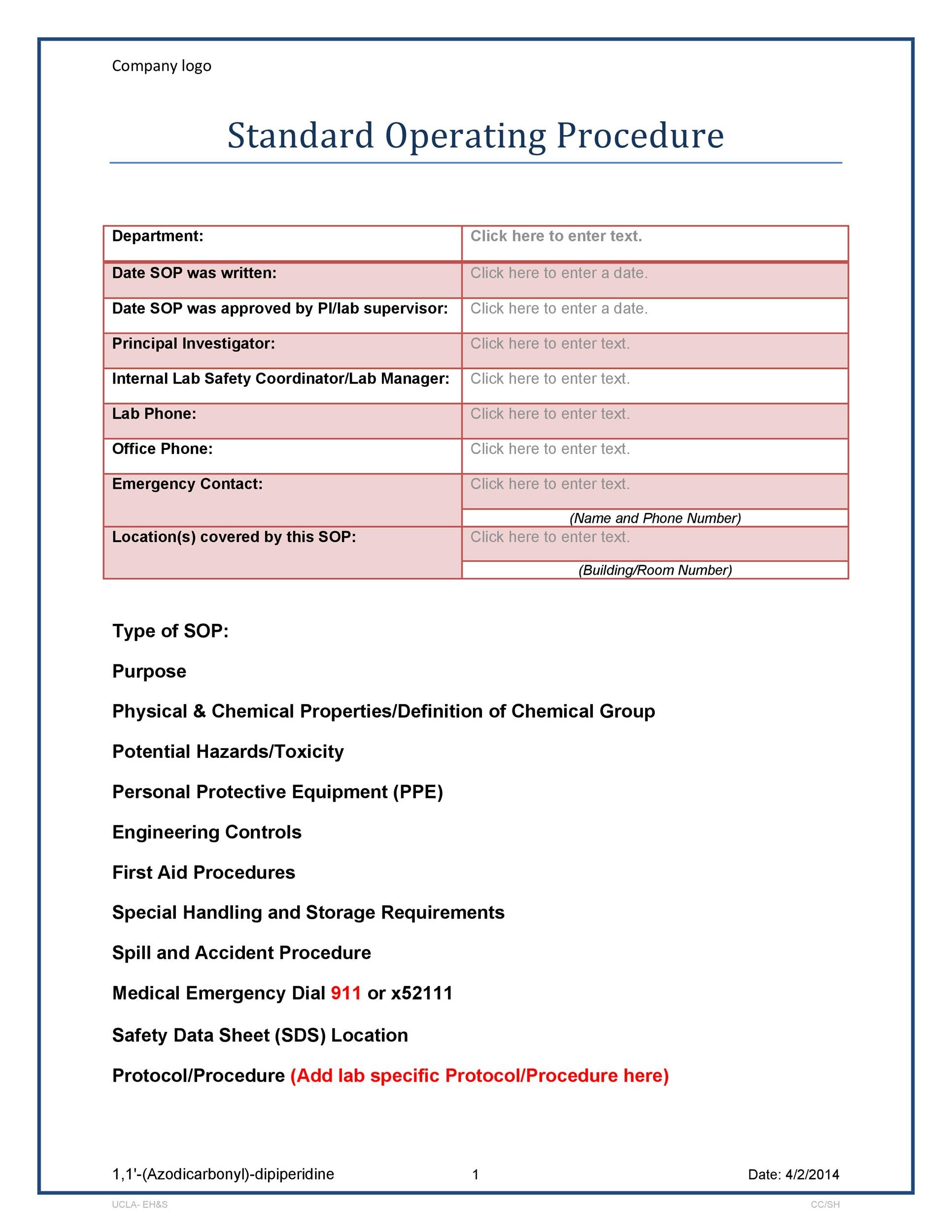

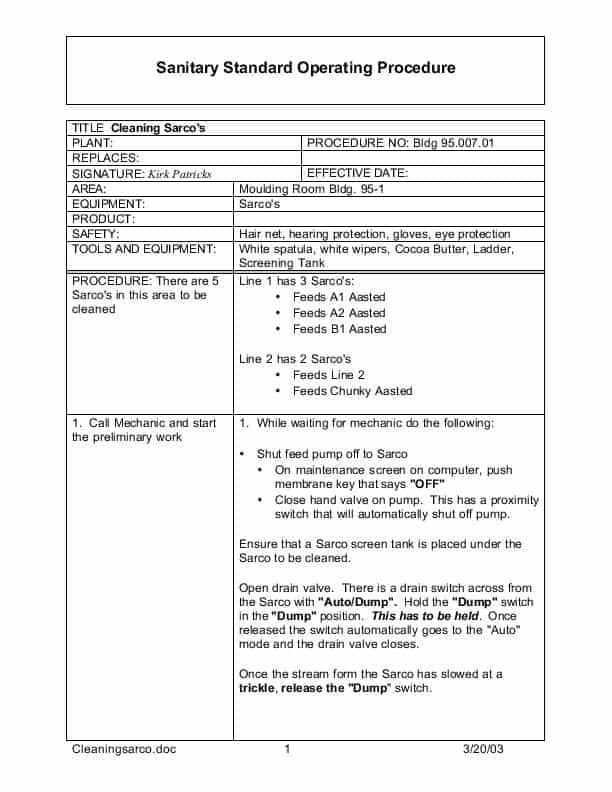

A standard operating procedure SOP is a detailed procedure that outlines the steps needed to complete specific tasks following your company or industry standards Technically any checklist or step by step instructions can be referred to as a procedure Writing Standard Operating Procedure Standard Operating Procedures SOPs are issued to specifically instruct employees in areas of responsibility Work Instructions appropriate specifications and required records SOPs outline procedures that must be followed to claim compliance with GMP principles or other Statutory rules and regulations

More picture related to Manufacturing Standard Operating Procedure

How To Write A Standard Operating Procedure A Practical Guide

https://econoshift.com/wp-content/uploads/2015/06/53-SOP-Competed.jpg

37 Best Standard Operating Procedure SOP Templates

https://templatelab.com/wp-content/uploads/2015/11/SOP-Templates-09.jpg

Write Standard Operating Procedures SOP The X Step Guide

https://www.thecloudtutorial.com/wp-content/uploads/2021/07/SOP-process-flow-chart-768x727.jpg

A Manufacturing Standard Operating Procedure SOP Plan is a set of detailed instructions and procedures that provide a consistent approach for how a specific task should be completed By following the same set of steps each time the SOP ensures that the manufacturing process is completed efficiently and consistently Standard operating procedures SOPs document this best practice so it is clearly understood by all Advantages of standards include They clearly demonstrate the best way to undertake a task Procedures help maintain quality by minimizing the likelihood of defects and process variation

The Quick Guide to Writing Standard Operating Procedures SOPs What is a Standard Operating Procedure Common Use Cases Why Write a Standard Operating Procedure The Most Important Things To Keep In Mind When Writing SOPs Where Do I Start And What Are The Main Steps What Do I Do With SOPs Once They Are Approved Additionally manufacturing standard operating procedures make it easier for managers to interpret key performance indicators KPIs Tracking maintenance and performance metrics is useless without understanding the step by step actions responsible for the data points Managers can share meaningful metrics with team members to help explain

45 Free Standard Operating Procedure Templates Word Excel Format

https://www.creativetemplate.net/wp-content/uploads/2017/10/SOP-Production-Process-Template.png

9 Standard Operating Procedure SOP Templates Word Excel PDF Formats

http://www.getwordtemplates.com/wp-content/uploads/2016/01/SOP-image-4.jpg

Manufacturing Standard Operating Procedure - A Manufacturing Standard Operating Procedure is a step by step instruction guide for carrying out specific tasks in a manufacturing process It is a foundational document that details the procedures to accomplish a particular job safely and effectively ensuring product quality and worker safety